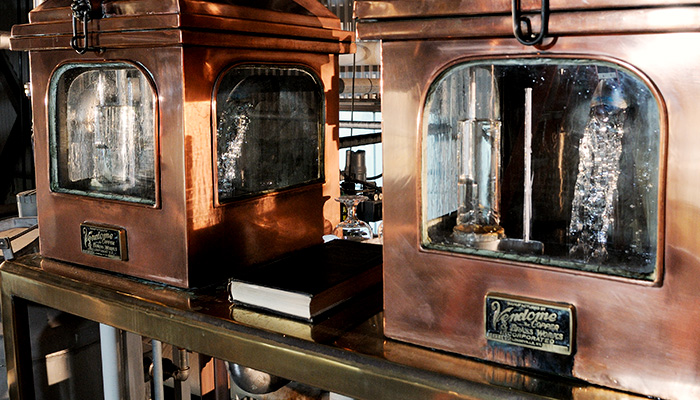

Discover the story behind our Bernheim Distillery, the largest independent, family-owned Bourbon Distillery in the world.

VIEW Our DistilleriesWe're proud of the spirits we've crafted right here in the heart of Bourbon

country. Discover the brands that have been Lifting Spirits since 1935.

Heaven Hill Distillery has been perfecting the craft of distilling, aging, and selecting award-winning whiskeys for decades.

Learn More

Since 1935, the Shapira family has been at the helm of the largest family-owned and operated distillery in America. Discover their quintessential American success story.

Learn More

For over 85 years, we've devoted ourselves to the craft of fine American Whiskey. We're proud of the spirits we've crafted, and grateful the critics agree.

Learn More

We’re proud to produce more Bottled-in-Bond products than any other American Whiskey distiller.

VIEW THE EXPERIENCE

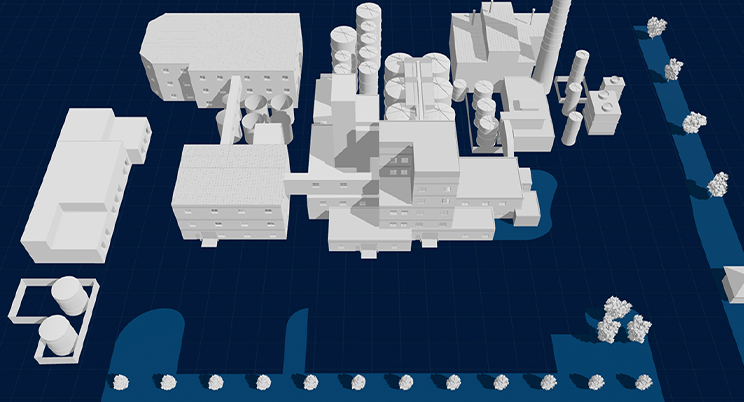

Just west of downtown Louisville sits Heaven Hill’s Bernheim Distillery—the only heritage distillery to produce every major style and type of American Whiskey, with five signature mashbills.

VIEW THE EXPERIENCE

Part of crafting high-quality whiskey for years to come involves protecting our natural resources.

Learn More

Cork is a 100% natural material that’s sustainable both environmentally and economically. It also happens to have much more in common with American Whiskey than you may think.

Learn More

Discover the people, places, and stories behind every step of our most adventurous whiskey production ever.

VIEW THE EXPERIENCE

Discover how our famed local water helps shape the flavor of American Whiskey.

VIEW THE EXPERIENCE

We've put together a guide to whiskey tasting for newcomers and experts alike. But remember, how you drink your whiskey is your decision. We’re just here to make sure it’s an experience you enjoy.

Learn More